June 9, 2025

OSAKA SEALING PRINTING CO., LTD.

Eco-friendly products that eliminate plastic films and reduce waste

Thermal paper bands using coating technology

Successfully developed "bundled direct thermal paper"

- OSAKA SEALING PRINTING CO., LTD.

- press release

OSAKA SEALING PRINTING CO., LTD. (Head office: Tennoji-ku, Osaka City; President: Matsuguchi Tadashi), a member of the OSP Group, is pleased to announce that it has succeeded in developing an environmentally friendly paper product, "Bindable Direct Thermal Paper" (patent pending).

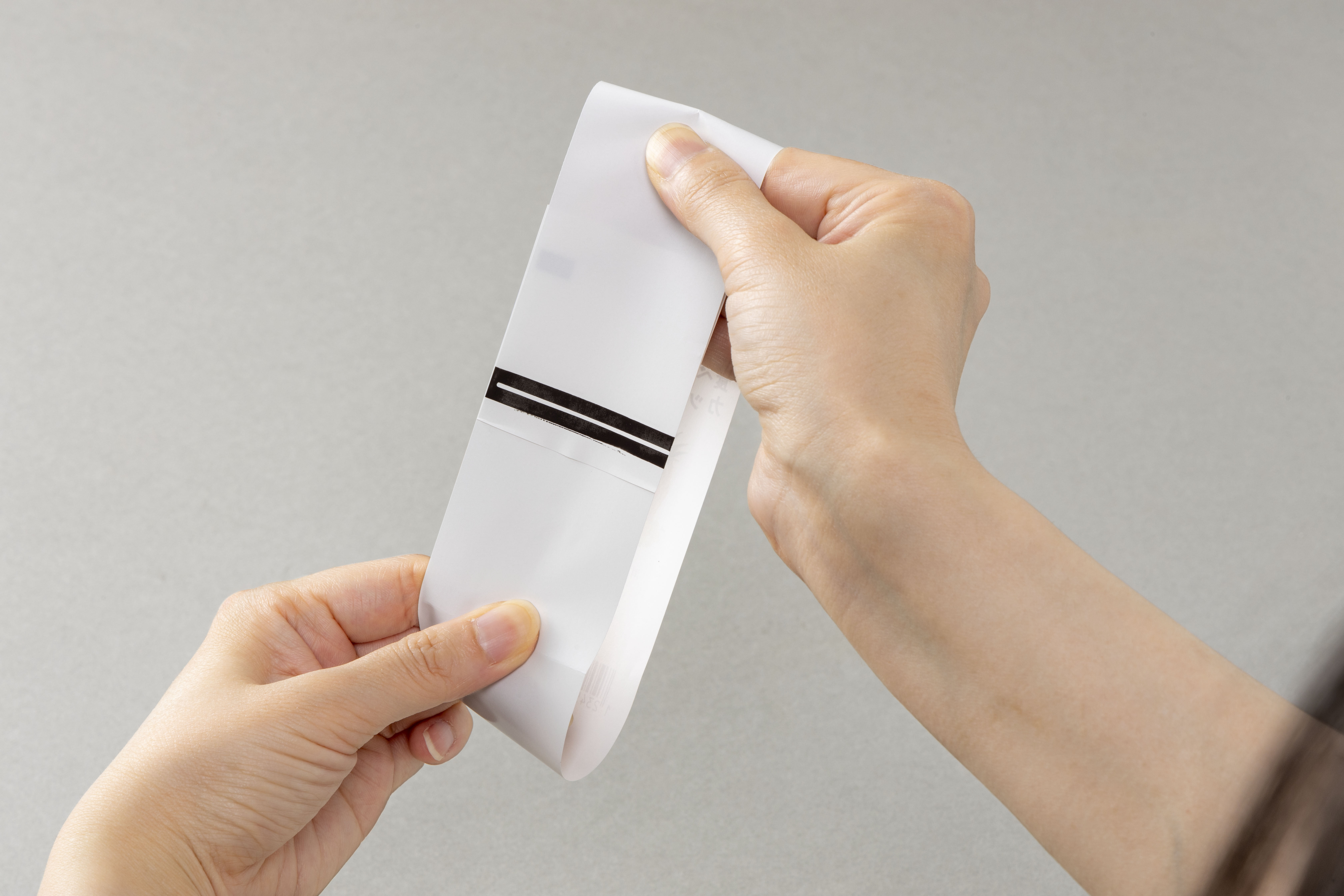

Conventional cable ties are mainly of the type with a silicone layer on the front and adhesive on the back, or of the type without a silicone layer on the front and with a plastic film laminated on the back. The front of this product is a thermal layer that allows direct thermal printing, and the back is coated with a heat seal layer, so it can be heat-pressed without using a plastic film.

■ Development Background

Recently, the movement to "eliminate plastic films" in order to reduce the environmental impact has been spreading, and many users are considering replacing plastic films in packaging materials with paper products. In bundling materials, too, there is an increasing shift from strong plastic films to paper products as an environmentally friendly option. In order to meet these market needs, we have begun developing products that can be used for thermal transfer ribbonless printing and bundling without using plastic films. The OSP Group is focusing on developing products that reduce the environmental impact not only in bundling materials but also in other packaging materials.

■ Advanced technical capabilities that solved the problem

The main feature of this product is that it can achieve direct thermal printing and thermocompression bonding at the same time. This is made possible by having two opposing properties: the thermal layer on the surface has excellent heat resistance against the thermal energy of the thermal head, while the heat seal layer on the back melts at a relatively low temperature. Furthermore, this product does not damage the thermal head during printing and maintains stable printing quality. Another feature is that it can avoid the adhesion of the front and back surfaces (blocking phenomenon) that tends to occur during normal storage in roll form. With tape-type bundling materials, there was a problem of the adhesive adhering to the products being bound, but this product solves this problem.

■Benefits of cost reduction and waste reduction

In the thermal transfer method using ink ribbons, the cost of the ribbon and the disposal of the film ribbon after use are issues, but direct thermal printing does not require a ribbon, so costs and waste can be significantly reduced. In addition, work efficiency is improved by eliminating the need to replace the ink ribbon.

■Realize roll-type products

When a plastic film is laminated on the back of paper, the paper may curl due to the effects of temperature and humidity, making it difficult to process smoothly in a packaging machine. However, this product overcomes this issue and is available in roll form, which makes the packaging process more efficient.

■Products that combine adhesiveness, ease of opening and cutting

This product has strong adhesive properties that will not loosen even when pulled vertically, allowing products to be securely bound together during transportation and when displayed in stores. When opening the package, the overlapping sheet can be easily peeled off by pulling it in the opposite direction to when it was glued, making unpacking extremely easy. Plastic film cannot be easily torn by hand, but this product is made of paper, so it can be torn from any point. Another major benefit is its ease of use for a variety of purposes.

■ Product Overview

Product name: Bindable direct thermal paper (tentative name)

Substrate: Thermal materials are BPA and BPS developer free

■ Product Overview

Product name: Bindable direct thermal paper (tentative name)

Base material: FSC™ certified paper, thermal material does not contain BPA or BPS developers

■Osaka Sealing Printing Company Profile

-

Company name: OSAKA SEALING PRINTING CO., LTD.

-

Address: 1-8 Obasecho-ku, Osaka City, Osaka Prefecture

-

Representative: Matsuguchi Tadashi

-

創業:1927年

-

Business description: Manufacturing and sales of stickers, labels, film products, Carton Package, and sales of labeling systems

■OSP Holdings Company Profile

-

Company name: OSP HOLDINGS CO., LTD.

-

Address: 6-8 Ajihara Honmachi Tennoji-ku, Osaka City, Osaka Prefecture

-

Representative: Matsuguchi Tadashi

-

Founded: 1969

-

Business description: Business planning and management of the corporate group and related operations

The OSP Group is a comprehensive packaging group with a total of 16 companies (9 domestic and 7 overseas), and has 18 production bases nationwide to fulfill its mission of social infrastructure, mainly food distribution. Since its founding in 1927, OSAKA SEALING PRINTING CO., LTD., one of the group companies, has expanded its business scope in response to changes in the times, such as customer needs and the social environment. Currently, the company provides products and services that enrich society and the lives of customers through the planning, design, and manufacturing of stickers and labels, film products, Carton Package, and promotional materials. In order to achieve high quality and stable supply, the group also operates in a wide range of areas, from material procurement, development and manufacturing of sticker and label printing base paper and printing peripherals, to designing and research and development of labeling systems.