OSPグループの環境方針

- 環境保全に配慮した商品開発を行う。

- 省エネルギーと省資源、環境負荷低減に役立つ施策の実施及び技術開発を行う。

- 廃棄物の減量化と資源リサイクルを推進する。

- 関連法規、地域協定、その他の要求事項の遵守を全員に周知し、維持する。

- 環境目的・目標を設定し、継続的改善と汚染の予防を図る。

CO₂排出量削減への取り組み

バイオマスボイラー

工場で発生する廃棄物を燃料とし、熱エネルギーとして活用しています。化石燃料の使用量を年間約274,000㎥削減しています。

輸送距離の削減

納品場所に合わせた生産工場の選択や、製品を在庫する地域を工夫することで、長距離輸送を削減しています。

LED照明の積極利用

工場内の照明と合わせ、インクを乾かすために使用しているUVランプもLEDへ順次変更し、使用エネルギーを削減しています。

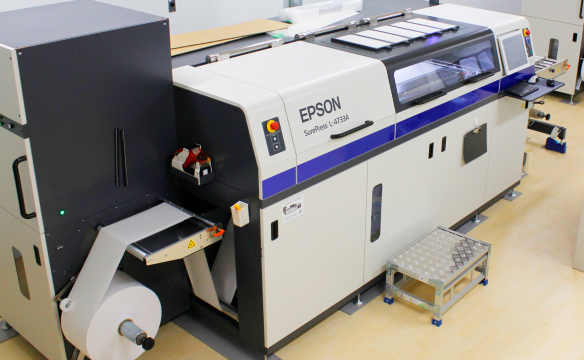

紙製品のデジタル印刷

他の印刷方法と比べ環境負荷の少ないデジタル印刷を推進。2021年度で約599tのCO₂削減につながりました。

バイオマスインキ

バイオマス由来材料を含んだインキや糊を使用した製品の販売にも取り組んでおります。バイオマス製品を普及させることで、大気中のCO₂の削減に貢献しています。

ノンソルベントラミネート加工の採用

OSPではラミネートのおよそ半数を溶剤不使用のノンソルベントラミネート加工へ置き換えを進めています。有機溶剤に起因する環境への負荷(CO₂・VOCの排出)を大きく削減できます。

環境に配慮した製品の開発

ペーパーアテンション

クリアペーパーシール

キュットカード

クリアラッピング

LIMEX Sheetを基材に使用したラベル

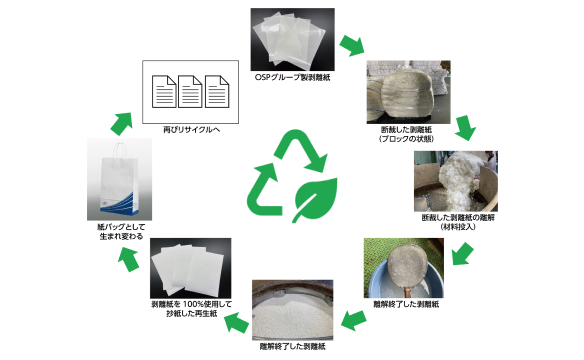

廃棄する剥離紙をリサイクル活用させた環境配慮型製品

剥離紙(セパレーター)を原料とした再生紙

アルカリ洗浄で剥離するラベル

2色発色のトップシールサーマル

水性グラビア印刷とノンソルベントラミネート加工の軟包材パッケージ

剥離紙がなく水性エマルションタイプの粘着剤を使用した貼り剥がし可能なラベル

バイオマス度10%以上の「バイオマス粘着剤ラベル」

ラベルの接着面に水をつけて貼り付けるサーマルテープラベル

その他の取り組み

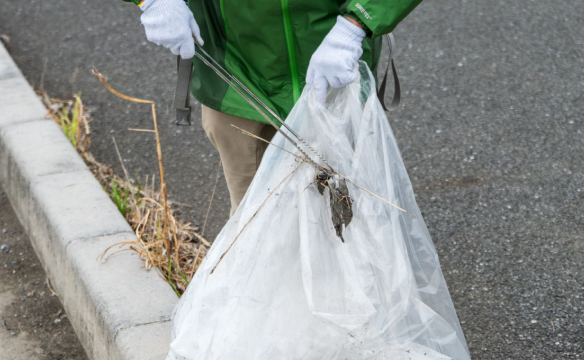

環境ボランティア活動

工場周辺の美化活動をおこない、清潔で美しい地域づくりに貢献しています。

エコバックの配布

OSPグループは全従業員約4000名に、エコバッグを配布しました。従業員一人ひとりが環境問題を身近に考えて欲しいという思いからです。OSPグループは、環境に配慮した製品や取り組みを創造してまいります。

スマートファクトリー

OSPグループでは、スマートファクトリーで工場内の様々な機器、材料、人をデジタルで捉え生産性の向上を目指しています。

森林認証(CoC認証)

森林や林産物の責任ある調達に対する国際的な認証である、FSC®CoC認証を取得しています。

ISO14001 環境マネジメントシステム

環境マネジメントに対する国際的な認証であるISO14001:2015を取得しています。

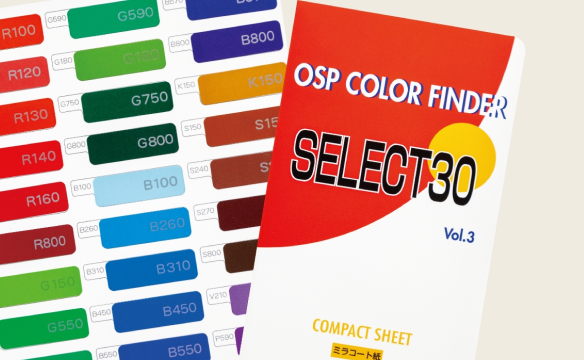

セレクト30

受注製品を分析し、使用頻度の高い30色を推進することで調色作業の効率化を図ります。またインキの洗浄に使用する有機溶剤の使用量を大幅に削減するように努めています。

「J-ECOL」設立に参加

環境負荷低減や循環型経済への対応を目指す組織一般社団法人ラベル循環協会「J-ECOL」を2023年6月に設立

伊吹山の自然保護に向けた取り組み

伊吹山の豊かな植生の保護を目的とした「伊吹山植生復元プロジェクト」の協定書を滋賀県米原市と締結しました。OSPグループは、地球温暖化対策や自然保護の持続的な推進を図ってまいります。

国際認証制度「RSPO」の準会員登録

持続可能なパーム油の生産・利用の促進を目的とした国際認証制度「RSPO」の取り組みに賛同し、準会員として登録しました。

ビールの麦芽粕を再生紙にして名刺を製作 売上金の一部をこども食堂へ寄付

オリオンビール株式会社と共同でビールの麦芽粕を使った再生紙を開発。その再生紙で名刺を製作し、売上の一部をこども食堂に寄付します。

「OSPグループとSDGs」

世界を変えるための17の目標「SDGs」の達成に向けて

OSPグループはSDGsに取り組み、人間と地球と繁栄のために、

より大きな自由における普遍的な平和を追求し、

事業活動を通して経済と社会と環境の調和を目指します。